In the early 1940’s Mr. William Heim like many Americans during this time was supporting the war effort by furnishing machined parts for the military through his company Service Machine Company. After the war in 1946 Mr. Heim purchased a company named the “David J. Ross Company”. The intent of this acquisition was for its machine tool capability. The David J. Ross Company also manufactured a 5 and 10 ton mechanical punch press under the trademark name of “ROUSSELLE”. While operating the company as a job shop many requests were received for replacement parts for the Rousselle existing product line as well as requests for new product. It was at this time that Mr. Heim saw the opportunity to continue the production of the Rousselle line and to develop new models with larger capacities to meet the metal stamping requirements of the next decade.

In the early 1940’s Mr. William Heim like many Americans during this time was supporting the war effort by furnishing machined parts for the military through his company Service Machine Company. After the war in 1946 Mr. Heim purchased a company named the “David J. Ross Company”. The intent of this acquisition was for its machine tool capability. The David J. Ross Company also manufactured a 5 and 10 ton mechanical punch press under the trademark name of “ROUSSELLE”. While operating the company as a job shop many requests were received for replacement parts for the Rousselle existing product line as well as requests for new product. It was at this time that Mr. Heim saw the opportunity to continue the production of the Rousselle line and to develop new models with larger capacities to meet the metal stamping requirements of the next decade.

During the 1950’s and 60’s the Rousselle press was manufactured in a modest facility on the south side of Chicago near 79th and Western Avenue. It was during this era that Mr. Heim brought the Rousselle press to the forefront of the stamping industry as well as a trademark name recognized within the industry around the world. To meet the growing demand of the industry Mr. Heim expanded the product range from the 5 and 10 ton simple OBI press, to press capacities up to and including 110 ton. Various models were designed such as horn; adjustable bed, deep throat, and a wide bed double crank series to meet the end users die requirements. He also established a design and manufacturing discipline based on standardization and interchangeability within models along with emphasis on value analysis. The goal… to offer end users an affordable quality product and be the best value available in the marketplace. With these principles Mr. Heim brought the Rousselle press from its infancy to be one of the largest volume producers of mechanical power presses in the world.

In the mid 1960’s Service Machine Company, being a successful company with a recognizable trademark name, caught the attention of large corporations looking for acquisitions for development of their conglomerate strategies. Alco Standard a large company trading on the New York Stock Exchange purchased the Rousselle product line from Mr. William Heim in 1968. Alco Standard operated the company from 1968 to 1984. During this time frame, following the philosophy and principles established by Mr. Heim had continued success in producing the Rousselle press. Alco also added to the product line larger presses to the capacity of 300 tons. With increased production requirements and larger capacity presses the manufacturing facility near 79th and Western Avenue was stressed beyond its limits. In 1976 Alco Standard built a new manufacturing facility in a new industrial area known as Bedford Park which is adjacent to Chicago on the south side just minutes away from Midway Airport.

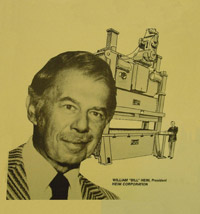

In 1968, still anxious to be in manufacturing, Mr. Heim built a new facility in Frankfort, Illinois a small town approximately 40 miles south of Chicago. Having signed a non-compete agreement with Alco Standard he could not manufacture a competitive press for a period of six years. With the metalforming and fabrication markets still strong he decided to manufacture a mechanical press brake under the brand name of “HEIM” that would not compromise the signed agreement with Alco Standard. Using the same design and manufacturing principles he established for the Rousselle product he developed a successful line of mechanical press brakes that ranged from 30 to 200 ton in capacity in various bed lengths. When the non-compete agreement expired with Alco Standard in 1974 he designed a line of steel fabricated series of presses also under the brand name of “HEIM” that competed directly with Alco Standard’s Rousselle press line.

In 1968, still anxious to be in manufacturing, Mr. Heim built a new facility in Frankfort, Illinois a small town approximately 40 miles south of Chicago. Having signed a non-compete agreement with Alco Standard he could not manufacture a competitive press for a period of six years. With the metalforming and fabrication markets still strong he decided to manufacture a mechanical press brake under the brand name of “HEIM” that would not compromise the signed agreement with Alco Standard. Using the same design and manufacturing principles he established for the Rousselle product he developed a successful line of mechanical press brakes that ranged from 30 to 200 ton in capacity in various bed lengths. When the non-compete agreement expired with Alco Standard in 1974 he designed a line of steel fabricated series of presses also under the brand name of “HEIM” that competed directly with Alco Standard’s Rousselle press line.

In 1984 Alco Standard had made a decision to spin off some of its acquisitions in certain manufacturing sectors and to divest itself from Rousselle and put the company up for sale. Mr. Heim again saw an opportunity to strengthen his position in the industry and purchased back the company he sold some 16 years ago. In reacquiring Rousselle and bringing the second generation family into the business, decisions were made to take the best of both product lines and manufacture both Heim and Rousselle presses in the Bedford Park facility. In melding the product together and to avoid confusion among the product overlaps the Rousselle brand was chosen to be press models 120 ton and under. The Heim brand name was chosen to remain on the mechanical press brake line and presses over 120 ton in capacity.

Now known as THE HEIM GROUP it is still a family owned business with the 3rd generation of the Heim family at the helm implementing the principles of standardization, interchangeability, and value analysis to offer the best valued press on the market.