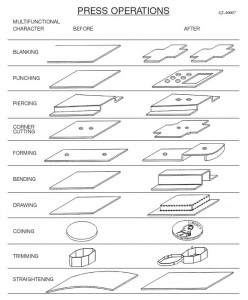

A variety of functions may be performed by any press, depending upon the tooling. Typical press operations are defined below:

Blanking – Cutting or shearing of outside contours or shapes from sheetor strip stock. The piece cut out is the useful part.

Coining – A squeezing operation, usually performed in a closed die in which the metal is forced to flow and fill the shape and profile of the die. There is a definite change in metal thickness.

Crimping – An operation in which the open end of a can or shell is forced tight over or around a mating part. This type of work is limited largely to assembly operations.

Curling – The forming of an edge having a circular cross section along a sheet or around the end of a shell or tube. This operation is sometimes called false wiring.

Drawing- A process in which a shell of any shape, is produced from flat sheet metal. Holding pressure is applied to the blank edge to prevent wrinkles in the flange as the punch forces the metal down into the die.

Embossing – A process for producing raised or sunken designs in sheet metal by means of a male and female die.

Extrusion – A process in which pressure is applied to a slug of metal causing the metal to flow either up around the punch (toothpaste tubes) or down in the direction of pressure (cartridge cases – Hooker process).

Ironing – A process in which the wall thickness of the shell is reduced without changing th O.D. of the shell (cartridge case work for example).

Lancing – Slitting and forming a pocket shaped opening in sheet metal, without removing metal.

Necking – Reducing the diameter of a portion of the length of a cylindrical shell or tube.

Piercing – Practically the same operation as blanking, except it is limited to holes or slots in sheet metal. The piece cut out is the scrap.

Redrawing – The second operation following deep-drawing operations, in which cups are deepened and reduced in cross section.

Staking – An operation in which two or more parts are assembled permanently by upsetting a small portion of metal over the mating part, causing the compression on the assembled parts.

Swaging – Forming a metal by the rapid striking of a large number of successive blows. In the case of aircraft cable fittings, the fitting is rotated while the press blows are being struck.

Trimming – A secondary operation on drawn or formed parts to remove excess metal on the flange or axial length.